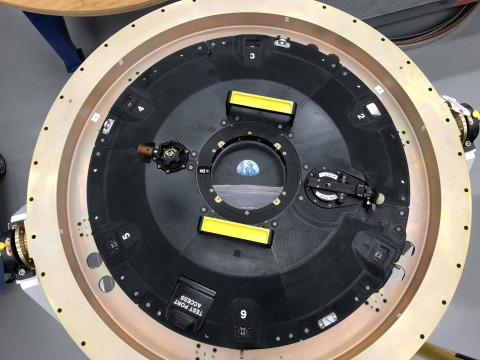

Through an iterative design approach, and a drastically reduced time to certification made possible by the Carbon Platform, production partner The Technology House (TTH) worked with NASA to rapidly and cost-effectively produce four high-performance thrusters for the cold-gas propulsion system within the new Seeker robotic free flier inspector. Seeker is a NASA free flyer technology demonstration project for autonomous robotic inspection that launched today aboard the Cygnus spacecraft for Northrop Grumman’s 11th contracted Commercial Resupply Services mission to the International Space Station (ISS).

Sidebar

Aerospace

EOS and Etihad Airways Engineering Set to Expand Industrial 3D Printing Capabilities

EOS, the world's leading technology supplier in the field of industrial 3D printing, and Etihad Airways Engineering, the largest aircraft maintenance, repair and overhaul (MRO) services provider in the Middle East, have agreed a strategic partnership which will significantly expand local capabilities for industrial 3D printing in aviation.

3D-Printed parts on site and on demand: Etihad Airways Engineering to use Bigrep 3D printers in their Maintenance, Overhaul and Repair facility.

Etihad Airways Engineering to install large-scale 3D printer Bigrep ONE to print parts and tooling, followed by a next generation Bigrep EDGE industrial 3D printer to develop, test and certify material for aircraft parts.

How EOS industrial 3D printing is contributing to revolutionizing human transport, enabling a pioneering flight suit

EOS and Gravity showcase aeronautical innovation at the formnext show in Frankfurt/Germany

EOS, the world's leading technology supplier in the field of Industrial 3D printing of metals and polymers, is showcasing its broad solution portfolio at formnext (Nov. 13 – 16) in Frankfurt/Germany. Based on a recently entered partnership with Gravity Industries, EOS will present components of Gravity's pioneering Jet Suit at the EOS booth G50 in hall 3.1. On November 14, show visitors can attend a demo flight performed by Gravity Industries, Head of Flight Training, Dr. Angelo Grubisic at the “Agora“ in front of hall 3 at 12.30h p.m.

World premiere in civil aviation with EOS technology

Liebherr - First metal 3D printed primary flight control hydraulic component flies on an Airbus A380

Today, the dream of flight revolves around producing aircraft components using industrial 3D printing technology. Every company aims to open up opportunities to differentiate themselves in the marketplace – in terms of new customer benefits, potential cost savings and sustainability targets. Thanks to EOS additive manufacturing technology, Liebherr is getting closer to achieving this goal. The realization of a high-pressure hydraulic valve block using EOS metal 3D printing technology marks an important milestone. This valve block has now been successfully tested on a flight with an Airbus A380 aircraft.

Sharing in Growth delivers success to LPW Technology in Aerospace Supply Chain

LPW Technology is delighted to have been awarded the Sharing in Growth (SiG) ‘Ikigai’ trophy, the top award at the SiG ALL ST

Material traceability key in industrial Additive Manufacturing for certified aerospace applications

Additive Industries and LPW sign agreement to integrate powder management for the MetalFAB1 systems

Turkish Aerospace Industries Chooses Dassault Systèmes for Turkey’s Largest Aviation Project

Turkish Aerospace Industries Chooses Dassault Systèmes for Turkey’s Largest Aviation Project

Turkish Aerospace will use the 3DEXPERIENCE platform for end to end development of next generation, multirole aircraft

More than 2,000 stakeholders will digitally collaborate across functions and organizations

Dassault Systèmes selected after comprehensive evaluation of market solutions

Lifeguards of the near future

As the manufacturing partner for Sanad Academy, the winner of the AED1million 2017 UAE Drones for Good prize, Immensa Technology Labs was faced with the task of redesigning and 3D printing the body of an Unmanned Aerial Vehicle (UAV) within a very short period of time. The decision to produce the drone using additive manufacturing was made only three weeks prior to the competition, at a time when the team at Sanad Academy realized that 3D printing was the only way by which they could realize their ambitious goals. Their aim was to manufacture a ‘lifeguard drone’ – a drone which did not only fly, but could also float on water and act as a lifebuoy for people who may be drowning.

THE ARMOR 3D PRINTING OFFERING HAS A NAME: KIMYA

Armor has been producing 3D printing filaments for 3 years now. Boosted by its initial successes, today the group offers a 360° range named Kimya, consisting of both materials and services dedicated to additive manufacturing (3D printing).

MISSION TO THE MOON: STRATASYS JOINS FORCES WITH LOCKHEED MARTIN AND PADT TO ENGINEER ADVANCED 3D PRINTED PARTS FOR NASA’S ORION MISSION

Stratasys 3D printers and materials provide extremely high levels of strength, durability and thermal properties to power missions to deep space

Variant of new Stratasys Antero™ 800NA, PEKK-based material offers electro-static dissipative (ESD) functionality for advanced mechanical, chemical, and thermal properties

Deutsch (Germany)

Deutsch (Germany)  Polski (PL)

Polski (PL)